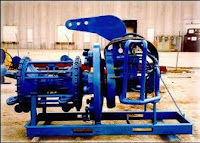

Pipe Facing Machine

Pipe Facing machine was developed to machine the

complex bevel required by the Pipeline

Welding System. Since its introduction in 1968, Pipe Facing Machine has been

used to make millions of bevels on pipes ranging from 4" to 64" in

diameter

The Pipe

Facing Machine is suspended from a side boom tractor.

The pipe

facing operation takes 2 to 5 minutes depending on the pipe wall thickness and

the skill of the operator.

Pipe Facing Machines are used for:

Producing clean, bright, perfect bevels for manual

pipeline welding to maximize quality minimize repairs.

Machining modified bevels on heavy wall pipe to reduce metal volume, therefore educing

welding time.

Machining mitered bevels up to 2-1/2 degrees

included angle on pipelines where it is not possible to use a Pipe Bending

Machine

Pipe

Facing Machine uses a combination of mechanical and hydraulic components to

produce bevels with a tolerance of ±0.005" (0.13mm). A hydraulic power

source is required.

Pipe Facing Machine has two major parts:

The clamp section The machining section