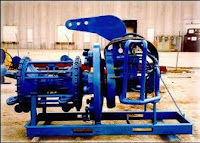

Pipe Facing Machine

Pipe Facing machine was developed to machine the

complex bevel required by the Pipeline

Welding System. Since its introduction in 1968, Pipe Facing Machine has been

used to make millions of bevels on pipes ranging from 4" to 64" in

diameter

The Pipe

Facing Machine is suspended from a side boom tractor.

The pipe

facing operation takes 2 to 5 minutes depending on the pipe wall thickness and

the skill of the operator.

Pipe Facing Machines are used for:

Producing clean, bright, perfect bevels for manual

pipeline welding to maximize quality minimize repairs.

Machining modified bevels on heavy wall pipe to reduce metal volume, therefore educing

welding time.

Machining mitered bevels up to 2-1/2 degrees

included angle on pipelines where it is not possible to use a Pipe Bending

Machine

Pipe

Facing Machine uses a combination of mechanical and hydraulic components to

produce bevels with a tolerance of ±0.005" (0.13mm). A hydraulic power

source is required.

Pipe Facing Machine has two major parts:

The clamp section The machining section

The clamp section:

The clamp section has two sets of hydraulically operated shoes that are mechanically interconnected so that they expand equally and simultaneously. The shoes secure the machine to the pipe end by expanding inside the pipe.

The machining section:

The

machining section of the Pipe Facing Machine consists of a rotating faceplate

with up to six radial arms holding cutting tools with tungsten-carbide tips. The

tools can be set to machine a wide range of bevel configurations. The faceplate

is rotated hydraulically. The face plate is fed by an independent hydraulic

system.

The recommended

manpower is one facing machine operator and one tractor operator.

(HPU)

can be used to power the Pipe Facing Machine. This unit is skid mounted and consists

of a prime mover, hydraulic pumps, oil reservoir, and hydraulic hoses for transferring

the power. Alternatively, power may be obtained from a tractor mounted hydraulic

power take-off.

The

standard Pipe Facing Machine with Hydraulic Power Unit is available for pipe

sizes 4" through 60". The machines are available for sale or lease.

CRCEvans maintains an extensive inventory of spare parts, consumable items and

tools.

Pipe bending machine World-class forming machines through Swedish engineering and decades of knowledge. Bluetooth controlled industry leading CNC software, upgrade your old machine!

ReplyDeleteVisit site :- http://swebend.com/